- 1 Core Safety Principles: The Role of Low Smoke Zero Halogen Compound Fire Safety

- 2 Quantifying Flammability: The Limiting Oxygen Index Test for LSZH Cables

- 3 Controlling Fire Severity: Heat Release Rate Standards for Rail Cables

- 4 Mitigating Risk: Smoke Density and Toxicity Testing for Transport

- 5 Hangzhou Meilin New Material Technology Co., Ltd.: Excellence in Cable Compound Engineering

- 6 Frequently Asked Questions (FAQ)

- 6.1 1. Why is the Limiting Oxygen Index Test for LSZH Cables critical for transport applications?

- 6.2 2. What is the main difference between LSZH and PVC in terms of fire safety byproducts?

- 6.3 3. What metric in Heat release rate standards for rail cables is most important for preventing flashover?

- 6.4 4. Which standards govern the necessary fire performance of LSZH Compounds For Transportation Cables in European rail?

- 6.5 5. What is the primary test used for Smoke density and toxicity testing for transport?

In global transportation sectors—including rail, marine, and aerospace—cable materials must adhere to the most rigorous safety standards designed for confined spaces. The core technical solution is the use of LSZH Compounds For Transportation Cables (Low Smoke Zero Halogen). Achieving compliance with complex standards like EN 45545-2 or NFPA 130 requires deep material engineering, specifically targeting low flammability, minimal heat output, and extremely low smoke toxicity.

ML-FH9002 90℃ irradiated halogen- free flame-retardant sheath material for marine cables

Core Safety Principles: The Role of Low Smoke Zero Halogen Compound Fire Safety

LSZH materials are chemically engineered to suppress fire and minimize harmful byproducts, a non-negotiable requirement for passenger safety.

Understanding the Mechanism: Halogen-Free Flame Retardancy

- **Mechanism:** Unlike halogenated polymers (like PVC) which release fire-suppressing but toxic hydrogen chloride gas, **LSZH Compounds For Transportation Cables** use metal hydroxide fillers (like ATH or MDH). Upon heating, these fillers decompose, releasing water vapor which cools the combustion zone and dilutes flammable gases.

- **Performance:** This endothermic decomposition is the basis for Low smoke zero halogen compound fire safety, providing a physical and thermal barrier to fire propagation without emitting corrosive or dense smoke.

Why Halogen-Free is Mandatory for Confined Transport Spaces

In confined transport environments (subway cars, aircraft cabins), passengers have limited escape routes, making every minute of visibility and clean air critical. Traditional PVC cables, which release dense, opaque, and highly corrosive smoke (HCl), dramatically reduce visibility and endanger electronic systems. LSZH compounds prevent this catastrophic loss of visibility and function.

Combustion Byproduct Comparison Table (LSZH vs. PVC)

| Material Type | Primary Combustion Byproduct | Smoke Density (Toxicity) |

|---|---|---|

| Standard PVC Compound | Hydrogen Chloride (HCl) Gas | Very High Density (High Toxicity/Corrosion) |

| LSZH Compound (High Performance) | Water Vapor (H₂O) | Very Low Density (Low Toxicity/Corrosion, the standard for Low smoke zero halogen compound fire safety) |

Quantifying Flammability: The Limiting Oxygen Index Test for LSZH Cables

Flammability is objectively measured by how much oxygen is required for a material to sustain combustion.

LOI Testing Protocol and Minimum LOI Thresholds

- **Protocol:** The **Limiting oxygen index test for LSZH cables** (ISO 4589) determines the minimum percentage of oxygen needed in a mixture of oxygen and nitrogen to sustain ignition and burning.

- **Thresholds:** While standard air is approximately 21% oxygen, high-performance LSZH compounds typically achieve an LOI of 35% or higher. This means they cannot self-sustain a flame in normal atmospheric conditions.

Relating LOI to Real-World Fire Propagation

A high LOI is the first indicator of superior flame resistance, showing that the material actively resists ignition. Coupled with low heat release, a high LOI ensures the fire will not spread rapidly from the cable, giving passengers and crew critical evacuation time.

Controlling Fire Severity: Heat Release Rate Standards for Rail Cables

Standards like EN 45545-2 classify cables based on their contribution to a developing fire, primarily focusing on heat release.

Cone Calorimetry (ISO 5660) and Peak Heat Release Rate (PHRR)

- **Test Method:** Cone calorimetry (ISO 5660) is used to determine the rate and total amount of heat released by a burning material. The Peak Heat Release Rate (PHRR) is the critical metric.

- **Requirement:** Heat release rate standards for rail cables mandate low PHRR values, as high heat output accelerates flashover and fire spread within a compartment. LSZH materials are engineered to have a suppressed PHRR compared to standard polymers.

Crucial Compliance: The EN 45545-2 Requirement Set

EN 45545-2 (Railway Applications) defines Hazard Levels (HL1, HL2, HL3) based on operating environment. Cables designated for HL3 service must meet the most stringent limits for flammability, heat release, and toxicity, often requiring LOI > 35%, very low PHRR, and minimal smoke opacity.

Mitigating Risk: Smoke Density and Toxicity Testing for Transport

Smoke management is arguably the most important safety factor in confined transport settings.

Measuring Visibility Loss (Smoke Density) (ISO 5659-2)

- **Test:** Smoke density and toxicity testing for transport utilizes a smoke chamber (e.g., ISO 5659-2) to measure the optical density of the smoke generated. Low density is measured by a high light transmission value (Dmax).

- **Impact:** High-performance LSZH Compounds For Transportation Cables ensure light transmission remains above 60% after 4 minutes, preserving visibility for evacuation and ensuring the reliable operation of emergency lighting.

Assessing Gas Toxicity and the Toxin Index

Toxicity is assessed by analyzing the concentration of harmful gases (CO, CO₂, NOx, SO₂, etc.) released during combustion. The Toxin Index quantifies the cumulative respiratory hazard. Successfully passing Smoke density and toxicity testing for transport requires the Toxin Index to remain below defined threshold values, typically demanding minimal release of acidic and asphyxiant gases.

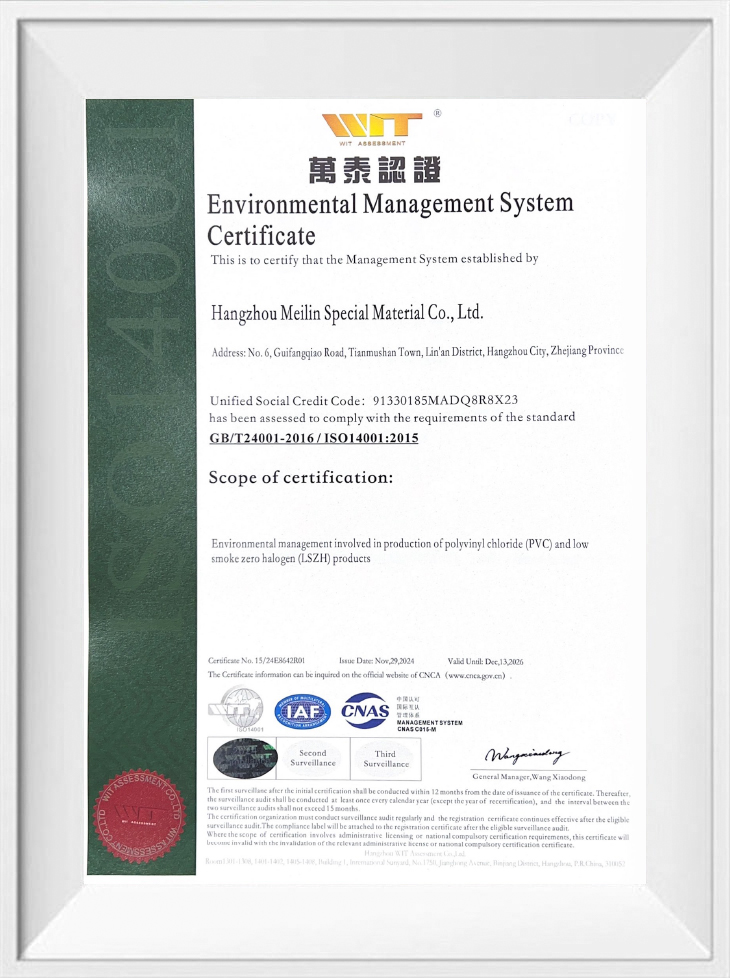

Hangzhou Meilin New Material Technology Co., Ltd.: Excellence in Cable Compound Engineering

Hangzhou Meilin New Material Technology Co., Ltd., founded in 1994, is a professional manufacturer of cable materials, including LSZH, PVC, FR-PE, and XLPE. With three modern production plants totaling over 40,000 square meters and 31 advanced automated production lines, we have established ourselves as a leader in the region. We employ senior engineers and a large technical management team, driving our output value past RMB 700 million in 2024. Our expertise lies in engineering specialized compounds, ensuring that our LSZH Compounds For Transportation Cables consistently achieve the stringent requirements for Heat release rate standards for rail cables and pass all necessary tests, including those for Smoke density and toxicity testing for transport. Our commitment to scientific development and sound management ensures we provide safe, reliable, and high-performance products to both domestic and international markets.

Frequently Asked Questions (FAQ)

1. Why is the Limiting Oxygen Index Test for LSZH Cables critical for transport applications?

The LOI test is critical because it quantifies the material's innate resistance to burning. A high LOI (typically > 35%) means the material cannot easily sustain combustion in normal air, which is the first step in fire prevention.

2. What is the main difference between LSZH and PVC in terms of fire safety byproducts?

PVC releases dense, corrosive hydrogen chloride (HCl) gas. Low smoke zero halogen compound fire safety relies on releasing non-toxic water vapor from inorganic fillers, drastically reducing smoke density and acidity.

3. What metric in Heat release rate standards for rail cables is most important for preventing flashover?

The Peak Heat Release Rate (PHRR), measured via Cone Calorimetry, is the most important metric. Low PHRR values ensure the cable contributes minimally to the fire's energy, slowing the time to flashover in confined spaces.

4. Which standards govern the necessary fire performance of LSZH Compounds For Transportation Cables in European rail?

The primary standard is EN 45545-2, which defines Hazard Levels (HL1 to HL3) and sets strict thresholds for flammability, heat release rate, and Smoke density and toxicity testing for transport depending on the operating environment.

5. What is the primary test used for Smoke density and toxicity testing for transport?

Smoke density is primarily tested using the ISO 5659-2 standard (smoke chamber) to measure optical density. Toxicity is assessed by analyzing the concentrations of harmful gases produced during the test.

English

English 中文简体

中文简体 русский

русский