- 1 Understanding the Material Science Behind ZPE and Traditional PE

- 2 Electrical Performance Comparison: ZPE vs Traditional PE

- 3 Mechanical and Physical Properties Analysis

- 4 Environmental Resistance and Long-Term Performance

- 5 Application-Specific Advantages of ZPE Compounds

- 6 Economic Considerations and Lifecycle Cost Analysis

- 7 Manufacturing and Quality Assurance Requirements

- 8 Future Developments and Industry Trends

- 9 FAQ

- 9.1 What are the main advantages of ZPE compounds over traditional PE for medium voltage power cables?

- 9.2 How does the cost of ZPE compounds compare to traditional PE, and is the premium justified?

- 9.3 Can ZPE compounds be processed using standard extrusion equipment for power cables?

- 9.4 What environmental benefits do ZPE compounds offer compared to traditional PE materials?

- 9.5 How do the mechanical properties of ZPE compounds impact cable installation and long-term performance?

The evolution of cable insulation materials has reached a significant milestone with the development of ZPE compounds for power cables, representing a substantial advancement over traditional polyethylene materials. As power transmission requirements become more demanding and environmental conditions more challenging, understanding the fundamental differences between these material technologies becomes essential for engineers, specifiers, and utility professionals. This comprehensive analysis examines the technical properties, performance characteristics, and application suitability of both materials in modern power transmission systems.

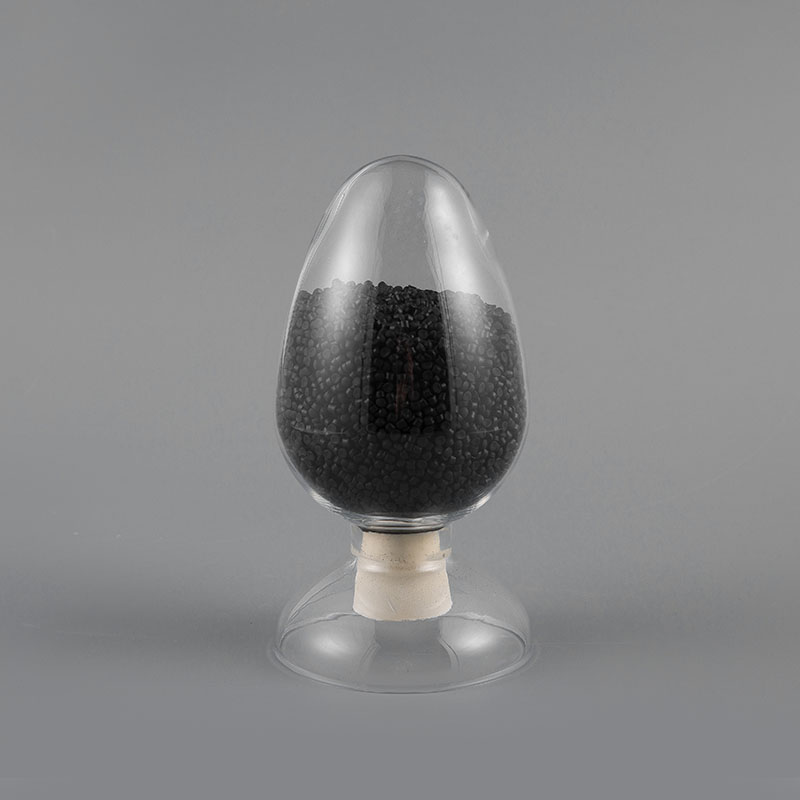

ML-ZRPE-H Flame-retardant polyethylene sheath material for high voltage cables

Understanding the Material Science Behind ZPE and Traditional PE

Zero Polyethylene Ethylene (ZPE) compounds represent a sophisticated advancement in polymer technology specifically engineered for high-performance power cable applications. Unlike traditional polyethylene materials that have served as industry standards for decades, ZPE insulation materials incorporate advanced molecular structures and proprietary additive technologies that fundamentally enhance their electrical, mechanical, and thermal performance characteristics. The development of these materials addresses the growing demands of modern power grids, renewable energy integration, and challenging installation environments.

- Molecular Architecture: ZPE features controlled chain branching and cross-linking capabilities absent in conventional PE

- Additive Technology: Advanced stabilization packages and property modifiers specifically engineered for electrical applications

- Crystallinity Control: Precisely engineered crystalline structures that balance flexibility and mechanical strength

- Interface Engineering: Enhanced compatibility with semiconductive layers and other cable components

- Manufacturing Precision: Requires sophisticated compounding technology and strict process control

Electrical Performance Comparison: ZPE vs Traditional PE

The electrical properties of insulation materials directly impact cable efficiency, reliability, and lifetime performance. ZPE compounds for power cables demonstrate significant advantages in key electrical parameters that translate to improved system performance, reduced losses, and enhanced operational reliability compared to traditional polyethylene materials.

Dielectric Properties and Loss Characteristics

Dielectric properties represent one of the most significant differentiators between ZPE insulation materials and traditional polyethylene. The advanced formulation of ZPE compounds results in superior dielectric strength, reduced dissipation factors, and enhanced resistance to partial discharge, making them particularly suitable for medium and high-voltage applications where electrical stresses are substantial.

- Dielectric Constant Stability: ZPE maintains consistent dielectric properties across temperature variations and aging

- Reduced Loss Tangent: Lower dissipation factors result in reduced dielectric losses and improved efficiency

- Partial Discharge Inception Voltage: Significantly higher thresholds for partial discharge initiation in ZPE materials

- Space Charge Accumulation: Advanced ZPE formulations minimize space charge buildup that can lead to premature failure

| Electrical Parameter | ZPE Compounds | Traditional PE |

| Dielectric Strength (kV/mm) | 35-50 | 20-30 |

| Dissipation Factor (50Hz) | 0.0002-0.0005 | 0.0005-0.001 |

| Volume Resistivity (Ω·cm) | >10^17 | 10^16-10^17 |

| Dielectric Constant (50Hz) | 2.2-2.3 | 2.3-2.35 |

Long-Term Electrical Aging Performance

The ability of insulation materials to maintain electrical integrity over decades of service represents a critical consideration for power cable applications. ZPE power cable materials demonstrate superior resistance to electrical aging mechanisms, including treeing resistance, oxidation stability, and thermal degradation, resulting in extended service life and reduced failure rates.

- Water Treeing Resistance: Advanced ZPE formulations exhibit exceptional resistance to water tree formation and propagation

- Oxidative Stability: Enhanced antioxidant systems provide superior protection against thermal-oxidative degradation

- Electrical Tree Inception: Higher voltage thresholds for electrical tree initiation and slower propagation rates

- End-of-Life Prediction:More predictable aging characteristics enabling accurate remaining life assessment

Mechanical and Physical Properties Analysis

Beyond electrical performance, mechanical and physical properties significantly influence cable design, installation feasibility, and long-term reliability. ZPE compounds for power cables offer a balanced combination of mechanical strength, flexibility, and environmental resistance that addresses limitations of traditional polyethylene materials.

Mechanical Strength and Durability

The mechanical properties of insulation materials impact cable handling during installation, resistance to mechanical damage, and long-term performance under various stress conditions. ZPE insulation materials provide enhanced mechanical characteristics while maintaining the flexibility required for modern cable designs and installation methods.

- Tensile Strength and Elongation: Optimized balance between strength and flexibility for different installation requirements

- Tear Resistance: Enhanced resistance to tear propagation, reducing installation damage risks

- Abrasion Resistance: Superior surface hardness and wear resistance compared to traditional PE

- Cut-Through Resistance: Improved resistance to compression and cutting forces during installation and service

| Mechanical Property | ZPE Compounds | Traditional PE |

| Tensile Strength (MPa) | 18-25 | 15-20 |

| Elongation at Break (%) | 450-600 | 400-500 |

| Young's Modulus (MPa) | 250-350 | 150-250 |

| Shore D Hardness | 55-65 | 50-60 |

Thermal Performance and Temperature Ratings

Thermal performance represents another area where ZPE power cable materials demonstrate significant advantages over traditional polyethylene. The enhanced thermal stability of ZPE compounds enables higher continuous operating temperatures, improved short-circuit withstand capabilities, and better performance in demanding thermal environments.

- Continuous Temperature Rating: ZPE typically rated 90°C compared to 75°C for standard PE

- Short-Circuit Withstand: Enhanced resistance to thermal shock during short-circuit conditions

- Thermal Aging Resistance: Superior retention of properties after extended thermal exposure

- Thermal Conductivity: Improved heat dissipation characteristics reducing hot spot temperatures

Environmental Resistance and Long-Term Performance

The ability of cable insulation to withstand environmental stressors throughout its service life directly impacts system reliability and maintenance requirements. ZPE compounds for power cables demonstrate enhanced resistance to various environmental factors that traditionally challenge polyethylene-based insulation systems.

Weathering and UV Resistance

For applications involving direct exposure to environmental elements, the weathering resistance of insulation materials becomes critical. Advanced ZPE compounds incorporate sophisticated stabilization systems that provide superior protection against UV radiation, thermal cycling, and oxidative degradation compared to traditional polyethylene formulations.

- UV Stabilization: Advanced hindered amine light stabilizers (HALS) and UV absorbers

- Hydrolysis Resistance: Enhanced resistance to moisture-induced degradation

- Thermal Cycling Performance: Maintains properties through repeated expansion and contraction cycles

- Chemical Resistance: Improved resistance to environmental contaminants and industrial chemicals

Application-Specific Advantages of ZPE Compounds

The selection between ZPE compounds for power cables and traditional polyethylene should consider specific application requirements, operating conditions, and performance expectations. ZPE materials offer particular advantages in demanding applications where enhanced performance justifies the typically higher material costs.

High-Voltage and Extra-High Voltage Applications

For transmission-level voltages, the superior electrical properties of ZPE insulation materials provide significant advantages in cable design, operational reliability, and lifetime performance. The enhanced dielectric strength, reduced losses, and improved partial discharge performance enable more compact designs and higher power densities.

- Reduced Insulation Thickness: Higher dielectric strength permits thinner insulation for equivalent voltage ratings

- Increased Power Density: Ability to transmit more power through cables of equivalent diameter

- Enhanced System Reliability: Reduced failure rates and extended service life in critical transmission circuits

- Improved Fault Withstand: Better performance during transient overvoltage conditions and fault situations

Renewable Energy and Harsh Environment Applications

The demanding conditions encountered in renewable energy applications, particularly in offshore wind, solar farms, and challenging geographical locations, benefit significantly from the enhanced properties of ZPE power cable materials. Their superior environmental resistance and mechanical durability address specific challenges in these applications.

- Offshore Wind Farms: Enhanced resistance to saltwater, humidity, and mechanical stresses

- Solar Applications: Superior UV resistance and temperature cycling performance

- Mountainous Terrain: Improved mechanical strength for difficult installation conditions

- Industrial Environments: Enhanced chemical resistance and temperature capabilities

| Application Scenario | ZPE Advantages | Traditional PE Limitations |

| Offshore Wind Export Cables | Superior water treeing resistance, enhanced mechanical durability | Vulnerable to water treeing, limited mechanical performance |

| Urban High-Voltage Networks | Reduced insulation thickness, higher power density | Thicker insulation required, lower power density |

| Industrial Power Distribution | Higher temperature rating, chemical resistance | Lower temperature capability, limited chemical resistance |

| Renewable Energy Collection | UV stability, thermal cycling performance | Limited UV resistance, property degradation with cycling |

Economic Considerations and Lifecycle Cost Analysis

While ZPE compounds for power cables typically command a price premium over traditional polyethylene materials, a comprehensive lifecycle cost analysis often reveals compelling economic advantages. The evaluation should consider not only initial material costs but also installation, operational, and lifetime maintenance expenses.

Total Cost of Ownership Analysis

The economic assessment of insulation materials should extend beyond simple price-per-kilogram comparisons to encompass the total cost of ownership throughout the cable system's operational life. ZPE power cable materials often demonstrate favorable economics when considering their extended service life, reduced losses, and lower maintenance requirements.

- Initial Cost Premium: ZPE typically costs 20-40% more than traditional PE compounds

- Installation Economics: Potential for reduced installation costs through lighter designs and easier handling

- Operational Efficiency: Reduced dielectric losses translating to lower operating costs over cable lifetime

- Maintenance and Replacement: Extended service life and reduced failure rates decreasing lifetime maintenance costs

Manufacturing and Quality Assurance Requirements

The production of high-performance ZPE compounds for power cables requires advanced manufacturing capabilities, sophisticated material expertise, and rigorous quality control systems. Established manufacturers like Hangzhou Meilin New Material Technology Co., Ltd. have developed specialized production technologies and quality assurance protocols to ensure consistent performance of these advanced materials.

- Advanced Compounding Technology: Precision control of molecular structure and additive dispersion

- Clean Manufacturing Environment: Strict contamination control to ensure electrical purity

- Comprehensive Testing: Extensive electrical, mechanical, and thermal performance verification

- Batch Traceability: Complete documentation and traceability from raw materials to finished product

- Technical Support: Engineering expertise to assist with material selection and application optimization

Future Developments and Industry Trends

The evolution of ZPE compounds for power cables continues as research addresses emerging challenges and opportunities in power transmission. Ongoing developments focus on enhancing specific properties, expanding application ranges, and improving sustainability profiles to meet evolving industry requirements.

- Higher Temperature Capabilities: Development of formulations suitable for 105°C and higher continuous operation

- Enhanced Sustainability: Incorporation of recycled content and bio-based components without compromising performance

- Smart Material Systems: Integration of functional properties for condition monitoring and predictive maintenance

- Application-Specific Formulations: Tailored compounds optimized for specific environmental and operational conditions

- Processing Optimization: Improved manufacturing efficiency and consistency through advanced process control

FAQ

What are the main advantages of ZPE compounds over traditional PE for medium voltage power cables?

ZPE compounds for power cables offer several significant advantages over traditional polyethylene in medium voltage applications, with improved electrical performance being the most notable. The enhanced dielectric strength allows for reduced insulation thickness while maintaining the same voltage rating, resulting in more compact cable designs. Superior water treeing resistance significantly extends cable life in wet environments, while higher temperature ratings enable increased current carrying capacity. Additionally, ZPE insulation materials demonstrate better partial discharge performance and reduced dielectric losses, contributing to improved system efficiency and reliability. These advantages become particularly valuable in applications where reliability, space constraints, or challenging environmental conditions are significant considerations.

ZPE power cable materials typically command a price premium of 20-40% over traditional polyethylene compounds, depending on specific performance requirements and formulation complexity. While this initial cost difference appears substantial, the premium is often justified when considering total lifecycle costs and performance benefits. The justification becomes clear through reduced dielectric losses over the cable's operational life, extended service life reducing replacement frequency, lower failure rates minimizing outage costs, and potential for more compact designs reducing installation expenses. For critical applications where reliability directly impacts operational continuity or safety, the enhanced performance of ZPE compounds for power cables typically provides compelling economic justification despite the initial cost premium.

Can ZPE compounds be processed using standard extrusion equipment for power cables?

Yes, ZPE insulation materials can generally be processed using standard extrusion equipment commonly employed for traditional polyethylene power cables, though some process optimization is typically required. The processing parameters for ZPE compounds, including temperature profiles, screw design, and cooling conditions, may need adjustment to accommodate their specific rheological characteristics and cross-linking requirements. Established material suppliers like Hangzhou Meilin New Material Technology Co., Ltd. provide comprehensive technical support and processing guidelines to facilitate smooth transition to ZPE compounds. While the fundamental extrusion principles remain consistent, optimal results with advanced ZPE compounds typically involve fine-tuning based on specific equipment characteristics and cable design requirements to fully realize their performance advantages.

What environmental benefits do ZPE compounds offer compared to traditional PE materials?

ZPE compounds for power cables offer several environmental advantages compared to traditional polyethylene materials, beginning with improved energy efficiency through reduced dielectric losses during power transmission. The extended service life of cables insulated with ZPE compounds reduces material consumption over time by delaying replacement cycles. Some advanced ZPE formulations incorporate enhanced recyclability characteristics and potential for incorporating bio-based content while certain proprietary formulations utilize additive systems with improved environmental profiles. The combination of reduced energy losses during operation and extended service life positions ZPE power cable materials favorably from a lifecycle environmental perspective, particularly in applications where efficiency and longevity are prioritized alongside initial environmental impact considerations.

How do the mechanical properties of ZPE compounds impact cable installation and long-term performance?

The mechanical properties of ZPE compounds for power cables significantly influence both installation feasibility and long-term reliability. The enhanced tensile strength and tear resistance of ZPE materials reduce the risk of installation damage during pulling through conduits or direct burial, particularly in challenging terrain. Improved abrasion resistance protects against surface damage during installation and throughout service life, while superior cut-through resistance provides better performance in applications where mechanical pressure might be applied to the cable. The balanced flexibility-stiffness relationship in ZPE insulation materials facilitates installation while maintaining necessary mechanical integrity, and enhanced resistance to environmental stress cracking ensures long-term performance in demanding conditions. These mechanical advantages translate to more reliable installations and reduced maintenance requirements over the cable's operational lifetime.

English

English 中文简体

中文简体 русский

русский