J-70 70℃ PVC Flame Retardant Soft Insulation Plastic is a high-performance wire and cable insulation...

ABOUT US

30YEARS OF

EXPERIENCE

About Us

Coming From China, Marketing To The World.

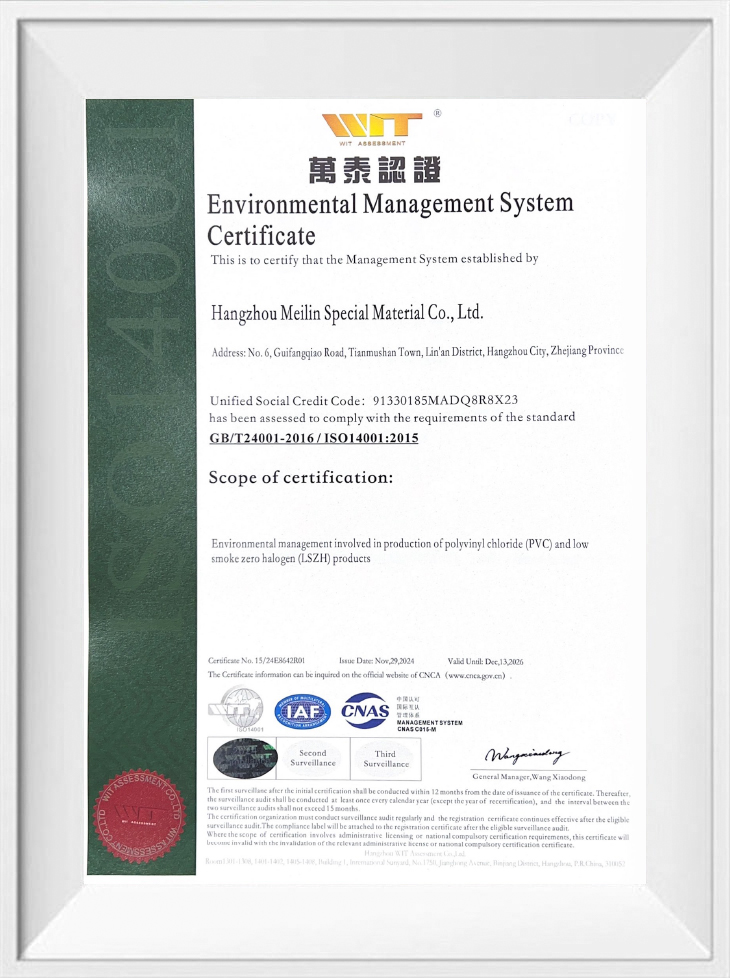

Hangzhou Meilin New Material Technology Co., Ltd. is China ODM/OEM Cloth Wire Cable Compound Suppliers and Wholesale Cloth Wire Cable Compound, we were established in July 1994 (formerly known as Zhejiang Lin'an Hongyan Plastic Factory). The company has two factories located at 619 Linglongshan Road and 259 Xingyu Street, Lingqiu Street, Linglong Industrial Park, Lin'an District, Hangzhou City. The registered capital of the company is 75 million yuan, covering an area of over 18000 square meters and a building area of over 30000 square meters. Currently, modern industrial factories and 18 advanced automated production lines have been built. The new factory area will be produced in 2021, making it the cleanest and most beautiful professional cable material manufacturer in the entire region—agreement conditions.

-

admin 12 Feb 2026

Why Are LSZH Compounds for Communication Cables Essentia...

Read MoreAs global data consumption surges, the architectural density of data centers and the complexity of public infrastructure have reached unprecedented levels. In these confined, high-value environments, ...

-

admin 04 Feb 2026

Meeting Global Compliance: Critical Requirements for PVC...

Read MoreThe global cable manufacturing landscape is undergoing a rigorous transition driven by stringent safety and environmental regulations. For industry professionals, understanding the technical nuances o...

-

admin 29 Jan 2026

Why Should You Switch to LSZH Compounds For Communicatio...

Read MoreIn the engineering of modern public infrastructure—such as subway systems, airports, and high-rise data centers—the selection of cabling materials is a critical safety decision. The transition from tr...

-

admin 22 Jan 2026

Navigating High-Speed Extrusion Challenges for LSZH Comp...

Read MoreAs global telecommunications infrastructure shifts toward 5G and high-density data centers, the demand for LSZH Compounds For Communication Cables has reached unprecedented levels. Unlike traditional ...

Cloth Wire Cable Compound Industry Knowledge

How Flame-Retardant Cloth Wire Cable Compounds Are Revolutionizing Industrial Safety

The demand for high-performance cloth wire cable compounds has surged in recent years, particularly in industries where fire safety is critical. Flame-retardant cloth-covered wiring is now a game-changer, offering enhanced protection against electrical fires while maintaining flexibility and durability.

Why Flame-Retardant Cloth Wire Compounds Matter

Traditional PVC or rubber-insulated cables can melt or ignite under extreme heat, posing severe risks in industrial settings. In contrast, fire-resistant cloth wire insulation uses advanced polymer blends with self-extinguishing properties, drastically reducing fire hazards.

Key Advantages of Flame-Retardant Cloth Cable Compounds

Superior Heat Resistance – These compounds can withstand temperatures up to 105°C to 150°C, far exceeding standard PVC wires (typically rated at 70°C–90°C).

Low Smoke & Toxicity – Unlike conventional cables, low-smoke zero-halogen (LSZH) cloth wire compounds minimize toxic fumes in case of fire, crucial for confined industrial spaces.

Enhanced Flexibility & Abrasion Resistance – The braided cloth wire coating provides mechanical strength, making it ideal for harsh environments like mining, oil & gas, and heavy machinery.

Industry Applications & Emerging Trends

Automotive & Aerospace – High-temperature cloth wire sheathing is increasingly used in engine compartments and aviation wiring due to its lightweight yet fireproof properties.

Renewable Energy Systems – Solar farms and wind turbines rely on UV-resistant flame-retardant cable compounds to prevent degradation and fire risks.

Industrial Automation – Factories adopting flexible fireproof cable solutions see fewer electrical failures, reducing downtime and maintenance costs.

Performance Comparison: Flame-Retardant vs. Standard Cables

| Parameter | Standard PVC Cable | Flame-Retardant Cloth Cable |

|---|---|---|

| Max Temp Resistance | 90°C | 150°C |

| Flame Spread | High | Self-extinguishing (UL94 V-0 rated) |

| Smoke Emission | High (toxic fumes) | Low (LSZH compliant) |

| Flexibility | Moderate | High (reinforced cloth braid) |

Future Outlook: Sustainable & Smart Cable Compounds

With stricter safety regulations, industries are shifting toward eco-friendly flame-retardant cable materials, including halogen-free compounds. Innovations like self-healing cloth wire insulation and smart cables with embedded sensors are also gaining traction.

English

English 中文简体

中文简体 русский

русский