ULH-80HDMI 80℃ UL Standard HDMI Sheath Compound is a material specially used for outer layer protect...

ABOUT US

30YEARS OF

EXPERIENCE

About Us

Coming From China, Marketing To The World.

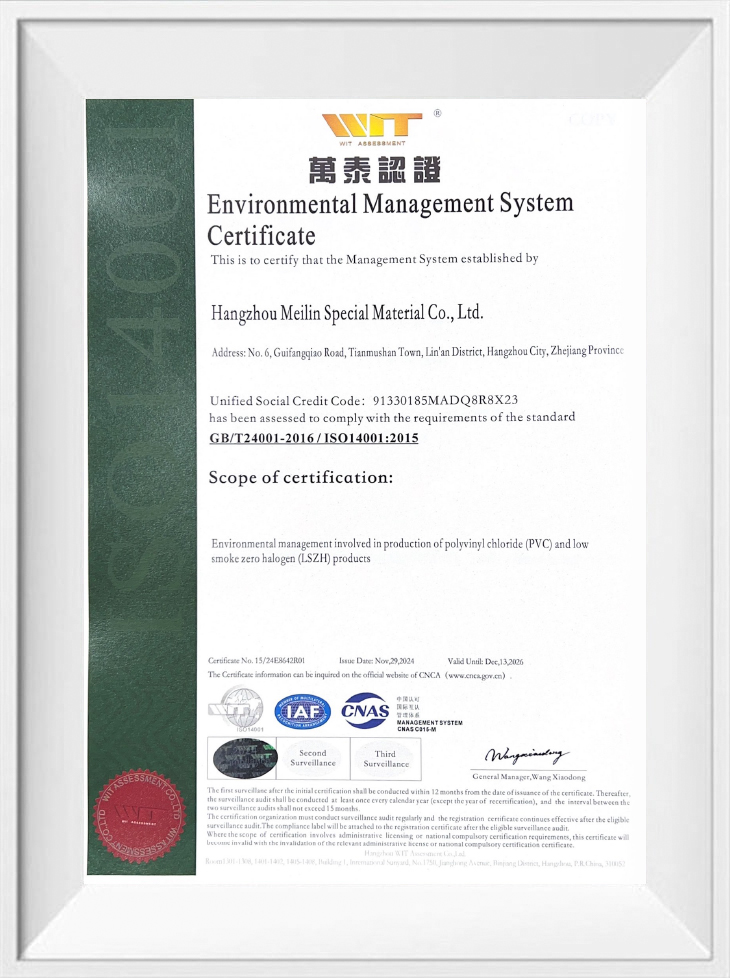

Hangzhou Meilin New Material Technology Co., Ltd. is China ODM/OEM Matte Data Cable Compound Suppliers and Wholesale Matte Data Cable Compound, we were established in July 1994 (formerly known as Zhejiang Lin'an Hongyan Plastic Factory). The company has two factories located at 619 Linglongshan Road and 259 Xingyu Street, Lingqiu Street, Linglong Industrial Park, Lin'an District, Hangzhou City. The registered capital of the company is 75 million yuan, covering an area of over 18000 square meters and a building area of over 30000 square meters. Currently, modern industrial factories and 18 advanced automated production lines have been built. The new factory area will be produced in 2021, making it the cleanest and most beautiful professional cable material manufacturer in the entire region—agreement conditions.

-

admin 12 Feb 2026

Why Are LSZH Compounds for Communication Cables Essentia...

Read MoreAs global data consumption surges, the architectural density of data centers and the complexity of public infrastructure have reached unprecedented levels. In these confined, high-value environments, ...

-

admin 04 Feb 2026

Meeting Global Compliance: Critical Requirements for PVC...

Read MoreThe global cable manufacturing landscape is undergoing a rigorous transition driven by stringent safety and environmental regulations. For industry professionals, understanding the technical nuances o...

-

admin 29 Jan 2026

Why Should You Switch to LSZH Compounds For Communicatio...

Read MoreIn the engineering of modern public infrastructure—such as subway systems, airports, and high-rise data centers—the selection of cabling materials is a critical safety decision. The transition from tr...

-

admin 22 Jan 2026

Navigating High-Speed Extrusion Challenges for LSZH Comp...

Read MoreAs global telecommunications infrastructure shifts toward 5G and high-density data centers, the demand for LSZH Compounds For Communication Cables has reached unprecedented levels. Unlike traditional ...

Matte Data Cable Compound Industry Knowledge

Analysis of the core performance and technical standards of Matte Data Cable Compound

Matte Data Cable Compound is popular in consumer electronics, smart devices and other fields due to its delicate touch, wear resistance, scratch resistance and high-end appearance. However, its performance requirements are far more than appearance, and it must also meet multiple technical standards such as electrical performance, mechanical strength, and environmental compliance.

Core performance indicators

Appearance and touch

Matte effect: It needs to be uniform and spot-free to avoid the "plastic feel" of traditional PVC or TPU.

Anti-fingerprint/anti-fouling: Surface treatment technology (such as adding special additives) reduces grease adhesion.

Mechanical properties

Abrasion resistance (ASTM D4060): No cracks after repeated bending (such as more than 100,000 times).

Flexibility (ISO 6722): It remains soft at low temperatures (-20℃ to -40℃) to avoid embrittlement.

Tensile strength (ISO 37): It is usually required to be ≥10MPa to ensure the durability of the cable.

Electrical properties

Dielectric constant and loss (IEC 60250): Affects high-speed data transmission (such as USB4/Thunderbolt 4).

Shielding effectiveness (EN 50396): Conductive fillers (such as carbon black) in composite materials need to balance matte and EMI shielding requirements.

Environmental adaptability

UV aging resistance (ISO 4892): Outdoor use must pass QUV test for more than 500 hours.

Flame retardant grade (UL 94/IEC 60332): At least VW-1 or HF1 level, meeting consumer electronics safety standards.

Environmental compliance

Halogen-free requirements (IEC 61249-2): Bromine/chlorine content <900ppm (such as EU RoHS, REACH).

Recyclability: Bio-based TPU or PP materials are gradually becoming a trend.

Industry technical standards

| Standard Category | Typical Standards | Key Requirements |

|---|---|---|

| Electrical Performance | IEC 61156 (Data Cable) | Impedance matching, transmission loss ≤0.2dB/m @1GHz |

| Flame Retardancy | UL 758 / CSA C22.2 | Self-extinguishing time <30s in vertical burn test |

| Environmental Compliance | RoHS 3.0 / REACH SVHC | Restricted substances (Cd, Pb, Hg, etc. ≤900ppm) |

| Mechanical Testing | EN 50575 (Building Cable) | Crush resistance, impact test, bending cycle test |

English

English 中文简体

中文简体 русский

русский