ULJ-105 YL UL105℃ Polyvinyl Chloride Sheath Compound for Medical Use is a special material designed ...

ABOUT US

30YEARS OF

EXPERIENCE

About Us

Coming From China, Marketing To The World.

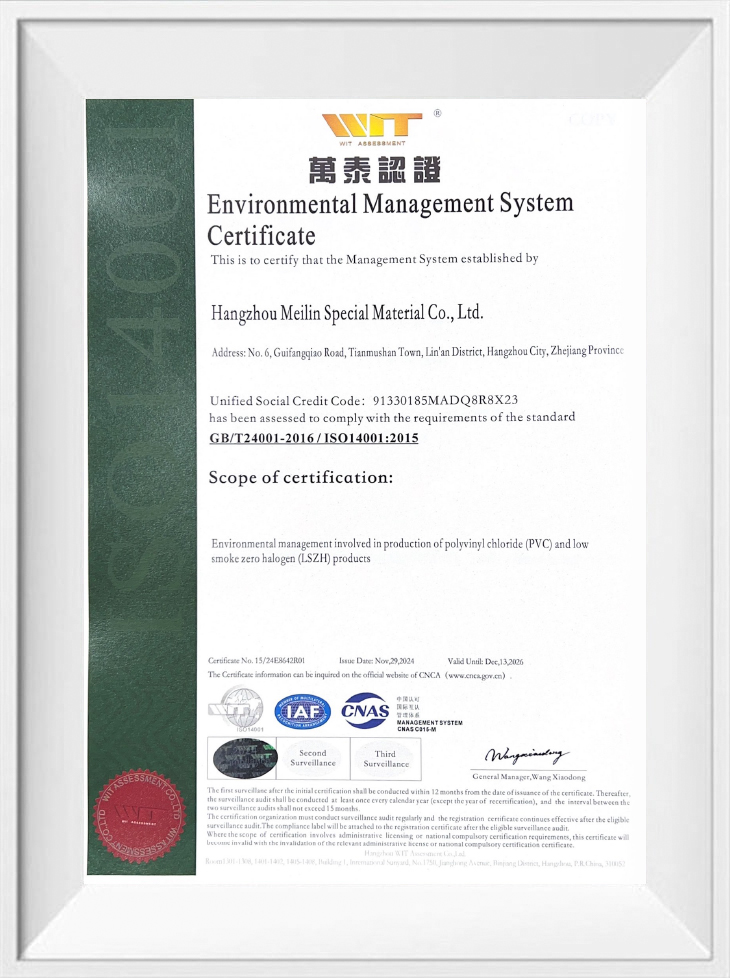

Hangzhou Meilin New Material Technology Co., Ltd. is China ODM/OEM PVC Cable Compound For Medical Equipment Suppliers and Wholesale PVC Cable Compound For Medical Equipment, we were established in July 1994 (formerly known as Zhejiang Lin'an Hongyan Plastic Factory). The company has two factories located at 619 Linglongshan Road and 259 Xingyu Street, Lingqiu Street, Linglong Industrial Park, Lin'an District, Hangzhou City. The registered capital of the company is 75 million yuan, covering an area of over 18000 square meters and a building area of over 30000 square meters. Currently, modern industrial factories and 18 advanced automated production lines have been built. The new factory area will be produced in 2021, making it the cleanest and most beautiful professional cable material manufacturer in the entire region—agreement conditions.

-

admin 12 Feb 2026

Why Are LSZH Compounds for Communication Cables Essentia...

Read MoreAs global data consumption surges, the architectural density of data centers and the complexity of public infrastructure have reached unprecedented levels. In these confined, high-value environments, ...

-

admin 04 Feb 2026

Meeting Global Compliance: Critical Requirements for PVC...

Read MoreThe global cable manufacturing landscape is undergoing a rigorous transition driven by stringent safety and environmental regulations. For industry professionals, understanding the technical nuances o...

-

admin 29 Jan 2026

Why Should You Switch to LSZH Compounds For Communicatio...

Read MoreIn the engineering of modern public infrastructure—such as subway systems, airports, and high-rise data centers—the selection of cabling materials is a critical safety decision. The transition from tr...

-

admin 22 Jan 2026

Navigating High-Speed Extrusion Challenges for LSZH Comp...

Read MoreAs global telecommunications infrastructure shifts toward 5G and high-density data centers, the demand for LSZH Compounds For Communication Cables has reached unprecedented levels. Unlike traditional ...

PVC Cable Compound For Medical Equipment Industry Knowledge

How Medical-Grade PVC Compounds Enhance Safety in Healthcare Wiring

The demand for high-performance PVC cable compounds for medical equipment is growing rapidly, driven by stringent safety regulations and the need for reliable wiring in healthcare environments. Medical-grade PVC compounds are specially formulated to meet critical requirements such as biocompatibility, flame resistance, and chemical stability, ensuring safe operation in sensitive medical applications.

Key Safety Enhancements of Medical-Grade PVC Compounds

1. Biocompatibility & ISO 10993 Compliance

Medical cables often come into direct or indirect contact with patients, making medical PVC compound biocompatibility a top priority. These compounds comply with ISO 10993 standards, ensuring they are non-toxic and non-irritating. Unlike standard PVC, medical-grade formulations avoid harmful plasticizers like DEHP, opting instead for safer alternatives such as non-phthalate PVC for medical devices.

2. Flame Retardancy & UL/CSA Certification

Healthcare facilities require wiring that minimizes fire risks. Flame-retardant PVC for medical cables meets UL 94 V-0 and IEC 60601-1 standards, ensuring self-extinguishing properties. Compared to generic PVC, medical-grade compounds exhibit:

| Property | Standard PVC | Medical-Grade PVC |

|---|---|---|

| Flame Retardancy (UL 94) | HB (Slow Burning) | V-0 (Self-Extinguishing) |

| Oxygen Index (%) | 20-25 | 28-35 |

| Smoke Density (NBS Smoke Chamber) | High | Low |

| Halogen Content | High (HCl emission) | Low/Controlled (LSHF options) |

| Compliance Standards | Basic electrical safety | UL 94 V-0, IEC 60601-1, CSA C22.2 No. 210 |

Key Takeaway: Medical-grade PVC compounds provide significantly better fire safety, making them essential for patient-connected devices, surgical equipment, and emergency medical systems where flame resistance is critical.

3. Chemical & Sterilization Resistance

Medical equipment often undergoes sterilization using autoclaving, ethylene oxide (EtO), or gamma radiation. Sterilization-resistant PVC cable materials maintain flexibility and durability even after repeated exposure, unlike conventional PVC, which may degrade.

4. Flexibility & Durability for Medical Cabling

Flexible PVC compound for medical wires ensures long-term reliability in dynamic applications like patient monitors and surgical tools. Key advantages include:

High tensile strength (≥15 MPa)

Low compression set for repeated bending

Resistance to oils and disinfectants

5. REACH & RoHS Compliance for Medical Applications

With increasing regulatory scrutiny, RoHS-compliant PVC for medical electronics eliminates hazardous substances like lead and cadmium. Low-smoke, halogen-free (LSHF) alternatives are also gaining traction in medical-grade wire and cable compounds for improved safety.

English

English 中文简体

中文简体 русский

русский