ULJ-105EV 105℃ Cold-Resistant -40℃ UL Standard Electric Vehicle Charging Cable Insulation Compound i...

ABOUT US

30YEARS OF

EXPERIENCE

About Us

Coming From China, Marketing To The World.

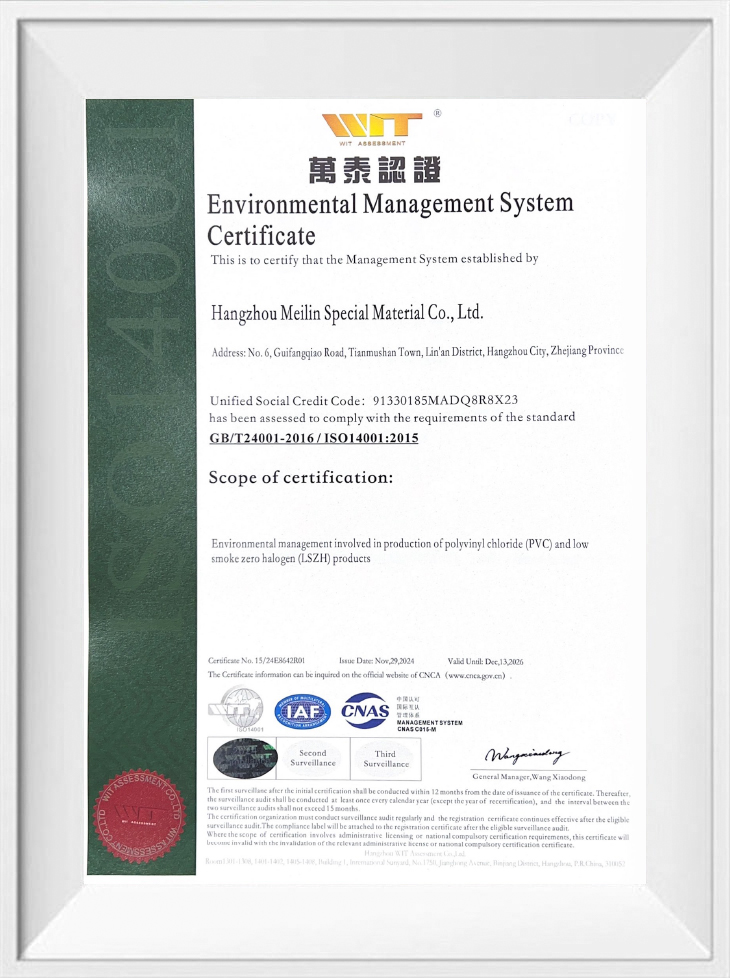

Hangzhou Meilin New Material Technology Co., Ltd. is China ODM/OEM External Car Charging Cable Materials Suppliers and Wholesale External Car Charging Cable Materials, we were established in July 1994 (formerly known as Zhejiang Lin'an Hongyan Plastic Factory). The company has two factories located at 619 Linglongshan Road and 259 Xingyu Street, Lingqiu Street, Linglong Industrial Park, Lin'an District, Hangzhou City. The registered capital of the company is 75 million yuan, covering an area of over 18000 square meters and a building area of over 30000 square meters. Currently, modern industrial factories and 18 advanced automated production lines have been built. The new factory area will be produced in 2021, making it the cleanest and most beautiful professional cable material manufacturer in the entire region—agreement conditions.

-

admin 12 Feb 2026

Why Are LSZH Compounds for Communication Cables Essentia...

Read MoreAs global data consumption surges, the architectural density of data centers and the complexity of public infrastructure have reached unprecedented levels. In these confined, high-value environments, ...

-

admin 04 Feb 2026

Meeting Global Compliance: Critical Requirements for PVC...

Read MoreThe global cable manufacturing landscape is undergoing a rigorous transition driven by stringent safety and environmental regulations. For industry professionals, understanding the technical nuances o...

-

admin 29 Jan 2026

Why Should You Switch to LSZH Compounds For Communicatio...

Read MoreIn the engineering of modern public infrastructure—such as subway systems, airports, and high-rise data centers—the selection of cabling materials is a critical safety decision. The transition from tr...

-

admin 22 Jan 2026

Navigating High-Speed Extrusion Challenges for LSZH Comp...

Read MoreAs global telecommunications infrastructure shifts toward 5G and high-density data centers, the demand for LSZH Compounds For Communication Cables has reached unprecedented levels. Unlike traditional ...

External Car Charging Cable Materials Industry Knowledge

What characteristics does the outer sheath material of the charging cable need to have to resist outdoor environmental factors such as ultraviolet rays, humidity and temperature changes?

The outer sheath material of the charging cable needs to have the following characteristics to resist outdoor environmental factors:

UV resistance: When exposed to sunlight for a long time, ultraviolet rays will cause the material to age, become brittle, and crack, reducing the insulation performance and mechanical strength of the cable. Therefore, the outer sheath material should have good UV aging resistance, be able to absorb or reflect ultraviolet rays, and reduce the damage of ultraviolet rays to the material. For example, polyvinyl chloride (PVC) materials containing ultraviolet absorbers such as carbon black can effectively improve the UV resistance of the cable sheath.

Moisture and waterproof performance: In outdoor environments, humid air, rain or snow may penetrate into the cable, causing problems such as conductor short circuit and reduced insulation performance. Therefore, the outer sheath material must have excellent moisture and waterproof performance, and usually uses materials with low water absorption and good sealing performance, such as thermoplastic elastomer (TPE), ethylene propylene rubber (EPDM), etc. These materials can prevent moisture intrusion and protect the internal structure of the cable from moisture.

High and low temperature resistance: A wide temperature range is one of the characteristics of the outdoor environment. Low temperature may make the material hard and brittle, and easy to break; high temperature may cause the material to soften and deform, affecting the performance and service life of the cable. The outer sheath material needs to maintain stable physical and mechanical properties over a wide temperature range. For example, silicone rubber has good high and low temperature resistance, can maintain good elasticity and flexibility in the temperature range of -50℃ to 200℃, and is suitable for various harsh outdoor temperature environments.

Mechanical strength and wear resistance: Outdoor cables may be subjected to various external forces, such as stretching, extrusion, friction, etc., so the outer sheath material needs to have sufficient mechanical strength and wear resistance to prevent the cable outer sheath from being damaged. Materials such as polyurethane (PU) have high hardness and wear resistance, can effectively resist external mechanical damage, and protect the conductor and insulation layer inside the cable.

Chemical corrosion resistance: Chemical substances in the outdoor environment, such as acid rain, oil pollution, dust, etc., may corrode the outer sheath material and reduce the performance of the material. Therefore, the outer sheath material should have good chemical corrosion resistance and be able to resist the erosion of various chemicals. Materials such as fluoroplastics have excellent chemical corrosion resistance and can remain stable in harsh chemical environments.

English

English 中文简体

中文简体 русский

русский