ML-FJ251R Flexible 125℃ Radiation Cross-Linked Halogen-Free Low Smoke Flame Retardant Cable Compound...

ABOUT US

30YEARS OF

EXPERIENCE

About Us

Coming From China, Marketing To The World.

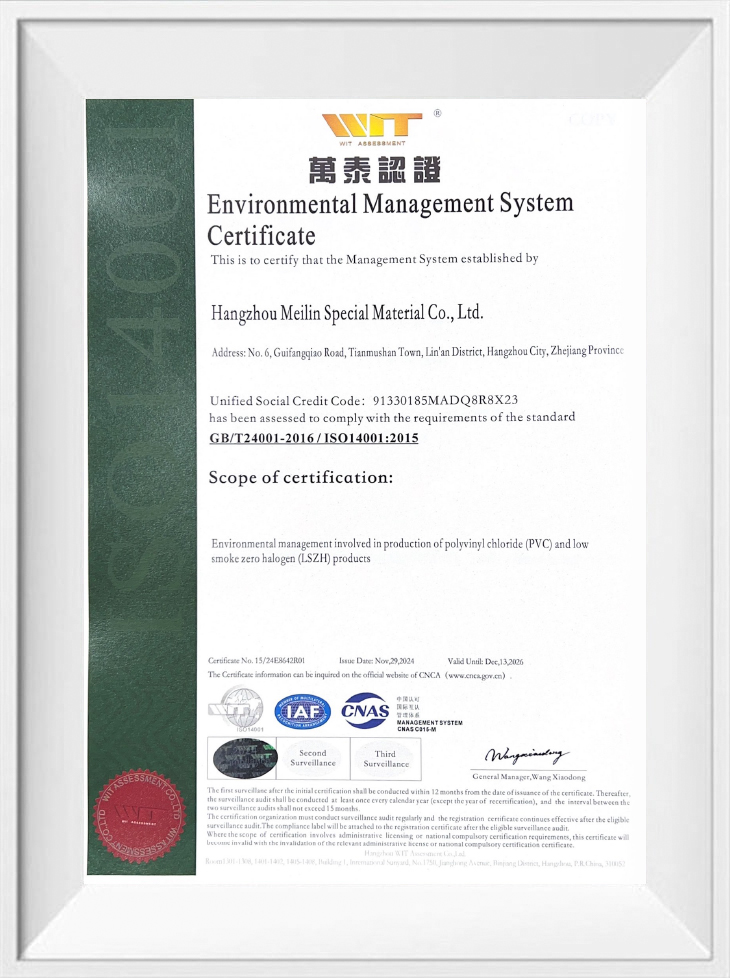

Hangzhou Meilin New Material Technology Co., Ltd. is China ODM/OEM High-voltage Automotive Cable Compound Suppliers and Wholesale High-voltage Automotive Cable Compound, we were established in July 1994 (formerly known as Zhejiang Lin'an Hongyan Plastic Factory). The company has two factories located at 619 Linglongshan Road and 259 Xingyu Street, Lingqiu Street, Linglong Industrial Park, Lin'an District, Hangzhou City. The registered capital of the company is 75 million yuan, covering an area of over 18000 square meters and a building area of over 30000 square meters. Currently, modern industrial factories and 18 advanced automated production lines have been built. The new factory area will be produced in 2021, making it the cleanest and most beautiful professional cable material manufacturer in the entire region—agreement conditions.

-

admin 12 Feb 2026

Why Are LSZH Compounds for Communication Cables Essentia...

Read MoreAs global data consumption surges, the architectural density of data centers and the complexity of public infrastructure have reached unprecedented levels. In these confined, high-value environments, ...

-

admin 04 Feb 2026

Meeting Global Compliance: Critical Requirements for PVC...

Read MoreThe global cable manufacturing landscape is undergoing a rigorous transition driven by stringent safety and environmental regulations. For industry professionals, understanding the technical nuances o...

-

admin 29 Jan 2026

Why Should You Switch to LSZH Compounds For Communicatio...

Read MoreIn the engineering of modern public infrastructure—such as subway systems, airports, and high-rise data centers—the selection of cabling materials is a critical safety decision. The transition from tr...

-

admin 22 Jan 2026

Navigating High-Speed Extrusion Challenges for LSZH Comp...

Read MoreAs global telecommunications infrastructure shifts toward 5G and high-density data centers, the demand for LSZH Compounds For Communication Cables has reached unprecedented levels. Unlike traditional ...

High-voltage Automotive Cable Compound Industry Knowledge

How can high-voltage automotive cable composite materials ensure good anti-interference performance in the complex electromagnetic environment of the car?

High-voltage automotive cable composite materials ensure good anti-interference performance in the complex electromagnetic environment of the car in the following ways:

Adopting a shielding structure: a metal shielding layer is set on the outside of the cable, such as copper or aluminum and other metal materials with good conductivity. The metal shielding layer can form an equipotential distribution, limit the electromagnetic field inside the cable to the shielding layer, reduce the leakage of electromagnetic signals to the outside, and also prevent external electromagnetic interference from entering the cable, playing a two-way shielding role. For example, the copper wire braided mesh is used as the shielding layer. The higher the braiding density, the better the shielding effect.

Choose the right insulating material: High-voltage automotive cable composite materials usually use insulating materials with high dielectric strength and low dielectric constant. High dielectric strength can ensure that the cable will not break down under high voltage, while low dielectric constant helps to reduce the electric field distortion inside the cable and reduce the generation of electromagnetic interference. For example, cross-linked polyethylene (XLPE) is a commonly used insulating material with good electrical and mechanical properties, which can effectively isolate the cable conductor from the external environment and reduce electromagnetic interference.

Optimize cable structure design: By rationally designing the cable structure, such as using a concentric twisted structure or a twisted pair structure, the electromagnetic field distribution inside the cable can be made more uniform, reducing the occurrence of electromagnetic coupling. The concentric twisted structure twists the conductors in layers according to certain rules to minimize the electromagnetic interaction between the conductors in each layer; the twisted pair structure twists the two conductors together so that the electromagnetic fields they generate cancel each other out, thereby reducing electromagnetic interference.

Add anti-electromagnetic interference additives: Add some special anti-electromagnetic interference additives to the cable composite material, such as nano-scale metal oxides or carbon nanotubes. These additives can form a conductive network inside the composite material, effectively absorb and dissipate electromagnetic energy, thereby improving the anti-interference performance of the cable. For example, adding carbon nanotubes can increase the conductivity of the composite material and attenuate electromagnetic interference inside the material.

Perform electromagnetic compatibility design: In the overall design stage of the car, the layout and direction of high-voltage automotive cables are reasonably planned to avoid laying cables in parallel with other strong electromagnetic interference sources at close distances to reduce the possibility of electromagnetic coupling. At the same time, electromagnetic compatibility design is also carried out on the cable's connecting components and terminal equipment to ensure that the entire cable system can operate stably and reliably in the complex electromagnetic environment of the car.

English

English 中文简体

中文简体 русский

русский