ZJ-70 70℃ PVC Flame Retardant Soft Insulation Plastic has high temperature resistance and can operat...

ABOUT US

30YEARS OF

EXPERIENCE

About Us

Coming From China, Marketing To The World.

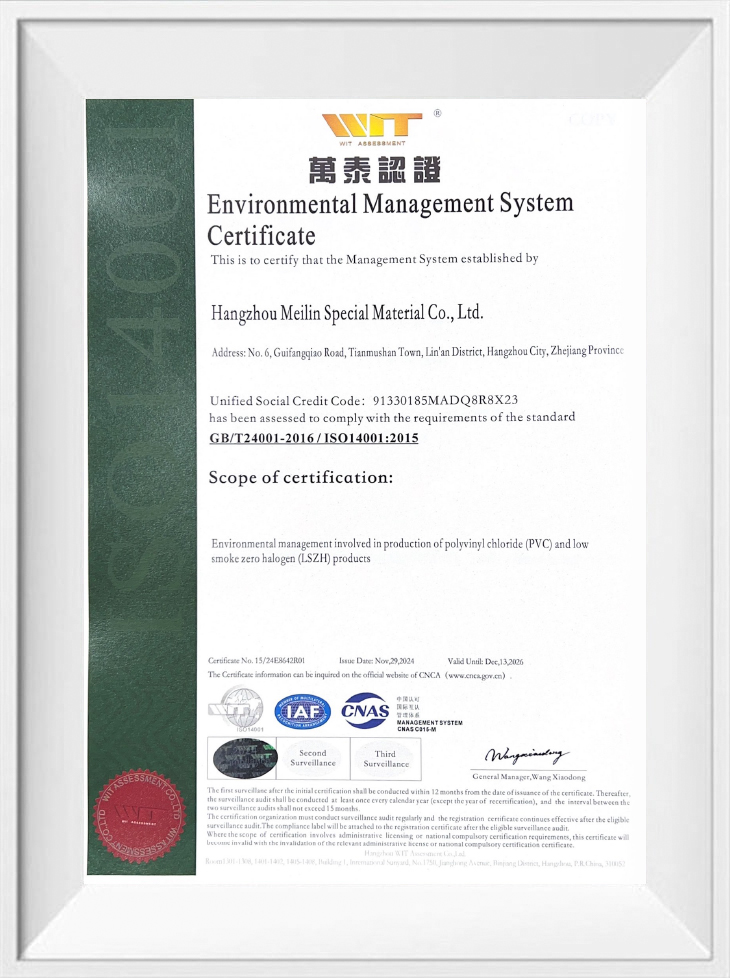

Hangzhou Meilin New Material Technology Co., Ltd. is China ODM/OEM Insulation Cable Compound Suppliers and Wholesale Insulation Cable Compound, we were established in July 1994 (formerly known as Zhejiang Lin'an Hongyan Plastic Factory). The company has two factories located at 619 Linglongshan Road and 259 Xingyu Street, Lingqiu Street, Linglong Industrial Park, Lin'an District, Hangzhou City. The registered capital of the company is 75 million yuan, covering an area of over 18000 square meters and a building area of over 30000 square meters. Currently, modern industrial factories and 18 advanced automated production lines have been built. The new factory area will be produced in 2021, making it the cleanest and most beautiful professional cable material manufacturer in the entire region—agreement conditions.

-

admin 12 Feb 2026

Why Are LSZH Compounds for Communication Cables Essentia...

Read MoreAs global data consumption surges, the architectural density of data centers and the complexity of public infrastructure have reached unprecedented levels. In these confined, high-value environments, ...

-

admin 04 Feb 2026

Meeting Global Compliance: Critical Requirements for PVC...

Read MoreThe global cable manufacturing landscape is undergoing a rigorous transition driven by stringent safety and environmental regulations. For industry professionals, understanding the technical nuances o...

-

admin 29 Jan 2026

Why Should You Switch to LSZH Compounds For Communicatio...

Read MoreIn the engineering of modern public infrastructure—such as subway systems, airports, and high-rise data centers—the selection of cabling materials is a critical safety decision. The transition from tr...

-

admin 22 Jan 2026

Navigating High-Speed Extrusion Challenges for LSZH Comp...

Read MoreAs global telecommunications infrastructure shifts toward 5G and high-density data centers, the demand for LSZH Compounds For Communication Cables has reached unprecedented levels. Unlike traditional ...

Insulation Cable Compound Industry Knowledge

What key performance indicators should be considered when selecting cable insulation materials?

When selecting cable insulation materials, a series of key performance indicators need to be considered to ensure that the cable can operate reliably in specific environments and conditions. Here are some common and important performance indicators:

1. Electrical performance

Dielectric strength: Dielectric strength refers to the maximum voltage that a material can withstand without breakdown. This performance directly affects the safety and reliability of the cable under high voltage.

Volume resistivity: Volume resistivity indicates the resistance of a material to the flow of current. The insulation layer of the cable needs to have a high volume resistivity to prevent current leakage.

Dielectric constant: The dielectric constant reflects the material's response to the electric field. For different applications, it may be necessary to select materials with a low dielectric constant to reduce electric field losses.

2. Thermal performance

Temperature resistance: The insulation material of the cable needs to have good high and low temperature resistance and be able to maintain its insulation function at extreme temperatures. Common cable insulation materials usually have different temperature resistance levels (such as 90°C, 105°C, 125°C, etc.).

Thermal stability: The thermal stability of a material determines its performance in a long-term high-temperature environment, including its anti-aging ability and non-deformation characteristics.

3. Mechanical properties

Tensile strength and elongation: Tensile strength refers to the maximum stress that a material can withstand before breaking under tension, while elongation reflects the ductility of the material when stretched. Higher tensile strength and elongation help ensure the durability of the cable during installation and use.

Abrasion resistance: Cables are susceptible to friction during laying, so it is necessary to select materials with good wear resistance to reduce damage to the insulation layer caused by friction loss.

4. Chemical stability

Chemical corrosion resistance: Insulating materials must be able to resist corrosion by chemicals such as acids, alkalis, salts, and solvents, especially in special environments such as petrochemicals and offshore platforms.

Hydrolysis resistance and oil resistance: When the insulating material of the cable comes into contact with water, oil and other substances, it must have good hydrolysis resistance and oil penetration resistance to avoid performance degradation.

5. Environmental adaptability

Weather resistance and UV resistance: Cables are usually exposed to the external environment and need good UV resistance and weather resistance to prevent damage from sunlight and weather changes.

Moisture resistance: Moisture or moisture may cause the cable insulation layer to age or break down, so the insulation material needs to have strong resistance to water vapor penetration.

6. Environmental protection and safety performance

Low smoke and halogen-free: Especially in places with high fire safety requirements, cable insulation materials need to have low smoke and halogen-free properties to reduce toxic gases and smoke when a fire occurs.

Non-toxicity: In extreme cases such as fire, the insulation material of the cable should not release harmful gases to ensure safety.

English

English 中文简体

中文简体 русский

русский