ML-WJ-90A original white 90A Polyvinyl Chloride Injection Compound For Toys is a high-quality materi...

ABOUT US

30YEARS OF

EXPERIENCE

About Us

Coming From China, Marketing To The World.

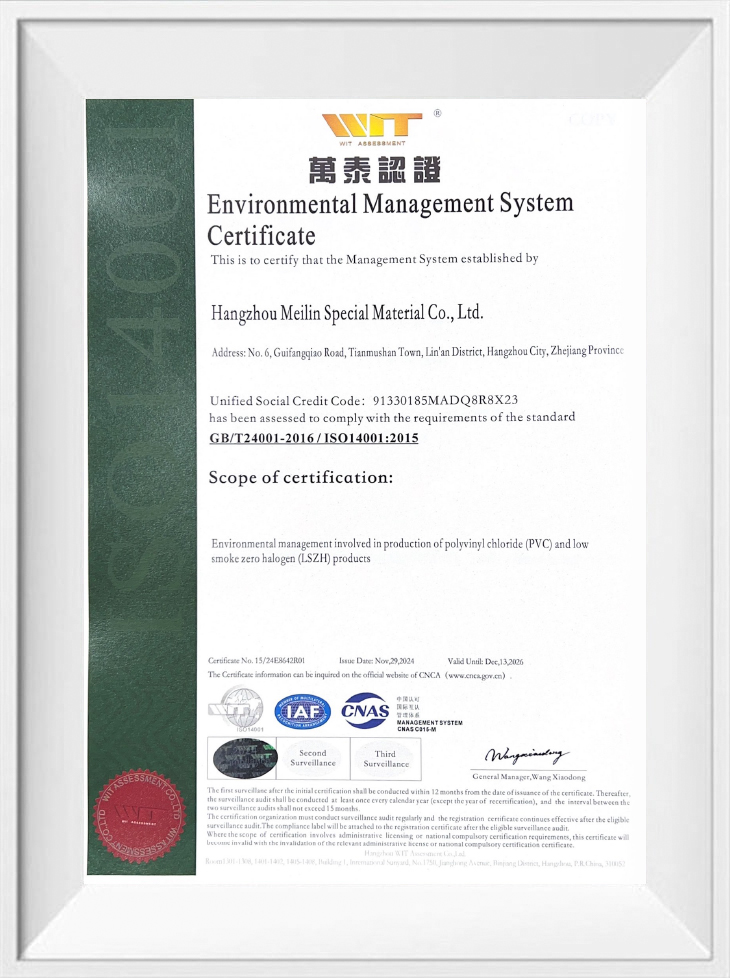

Hangzhou Meilin New Material Technology Co., Ltd. is China ODM/OEM Toy Materials Suppliers and Wholesale Toy Materials, we were established in July 1994 (formerly known as Zhejiang Lin'an Hongyan Plastic Factory). The company has two factories located at 619 Linglongshan Road and 259 Xingyu Street, Lingqiu Street, Linglong Industrial Park, Lin'an District, Hangzhou City. The registered capital of the company is 75 million yuan, covering an area of over 18000 square meters and a building area of over 30000 square meters. Currently, modern industrial factories and 18 advanced automated production lines have been built. The new factory area will be produced in 2021, making it the cleanest and most beautiful professional cable material manufacturer in the entire region—agreement conditions.

-

admin 12 Feb 2026

Why Are LSZH Compounds for Communication Cables Essentia...

Read MoreAs global data consumption surges, the architectural density of data centers and the complexity of public infrastructure have reached unprecedented levels. In these confined, high-value environments, ...

-

admin 04 Feb 2026

Meeting Global Compliance: Critical Requirements for PVC...

Read MoreThe global cable manufacturing landscape is undergoing a rigorous transition driven by stringent safety and environmental regulations. For industry professionals, understanding the technical nuances o...

-

admin 29 Jan 2026

Why Should You Switch to LSZH Compounds For Communicatio...

Read MoreIn the engineering of modern public infrastructure—such as subway systems, airports, and high-rise data centers—the selection of cabling materials is a critical safety decision. The transition from tr...

-

admin 22 Jan 2026

Navigating High-Speed Extrusion Challenges for LSZH Comp...

Read MoreAs global telecommunications infrastructure shifts toward 5G and high-density data centers, the demand for LSZH Compounds For Communication Cables has reached unprecedented levels. Unlike traditional ...

Toy Materials Industry Knowledge

Non-Toxic PVC Injection Compounds for Child-Safe Toys: 2024 Compliance Updates

The demand for PVC injection molding compounds for toys has surged in recent years, driven by stricter safety regulations and growing consumer awareness of phthalate-free PVC for children's products. As manufacturers seek high-flow PVC compounds for intricate toy designs, compliance with international standards like EU REACH, CPSIA (USA), and EN 71-3 remains a top priority.

Key Trends in Non-Toxic PVC Compounds for Toys

1. Phthalate-Free Plasticizers: Meeting Global Safety Standards

Traditional flexible PVC for soft toys often relied on phthalate-based plasticizers, which are now restricted due to health concerns. Alternatives like DINCH, DOTP, and bio-based plasticizers are gaining traction, offering low-migration PVC formulations that comply with FDA and EU Toy Safety Directive 2009/48/EC.

Performance Comparison:

| Property | Phthalate (DEHP) | Non-Phthalate (DINCH) |

|---|---|---|

| Flexibility | Excellent | Good |

| Migration Risk | High | Low |

| Cost | Low | Moderate-High |

2. Heavy Metal-Free Stabilizers for PVC Toy Compounds

To meet EN 71-3 heavy metal limits, manufacturers are shifting from lead and cadmium-based stabilizers to calcium-zinc (Ca-Zn) stabilized PVC. These eco-friendly PVC stabilizers ensure low toxicity while maintaining thermal stability during injection molding of PVC toy parts.

3. High-Flow PVC for Complex Toy Molds

Low-viscosity PVC injection grades are essential for producing detailed action figures, dolls, and educational toys. Compounds with MFI (Melt Flow Index) >15 g/10min enable faster cycle times and reduced warpage—key for high-volume toy production.

4. Sustainable PVC Blends & Recycled Content

With rising demand for green PVC compounds, some manufacturers now incorporate post-industrial recycled PVC (rPVC) while maintaining mechanical strength and color consistency. However, virgin PVC for medical and toy applications remains dominant due to purity requirements.

2024 Regulatory Updates Impacting PVC Toy Compounds

EU REACH SVHC List Expansion: New additives under scrutiny for endocrine disruption risks.

US CPSC Stricter Lead Limits: Lower thresholds for PVC-based children's products.

China GB 6675-2023 Updates: Enhanced migration testing for soft PVC toys.

English

English 中文简体

中文简体 русский

русский